MECHANICAL DESIGN AND ANALYSIS

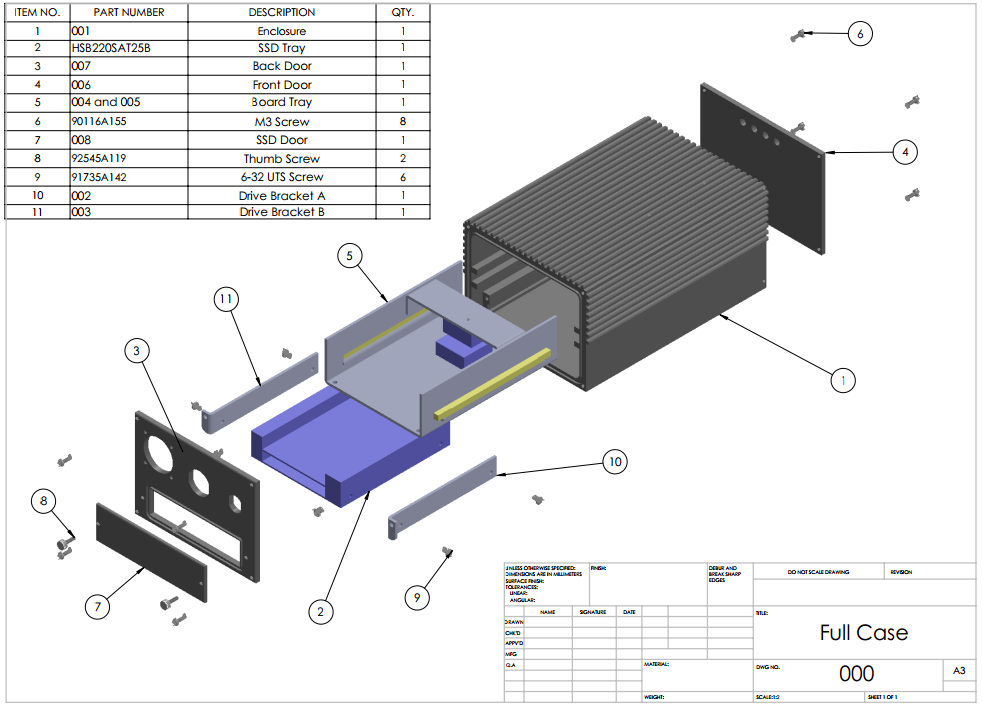

Our Mechanical Design team has expertise to develop rugged custom enclosures for a wide variety of electronics including handheld devices, rugged enclosure for aerospace applications, sensors, automotive etc.. The project steps start with your ideas and visions. This turns into an industrial design, followed by detailed mechanical drawings and then rapid prototypes. We can design rugged enclosure with detailed structural and thermal analysis.

OUR MECHANICAL SYSTEMS AND STRUCTURAL ENGINEERING SERVICES INCLUDE:

- Detail engineering

- Concept Design and Styling

- Cast / Forged / Plastic / Sheet Metal Component Design

- Re-Engineering / Reverse Engineering

- Parametric Design of Systems and Sub-Systems

- Design for Manufacturing / Assembly

- Mechanism Study, Simulation & Digital Mock-ups

- Engineering analysis (Finite element analysis and thermal analysis)

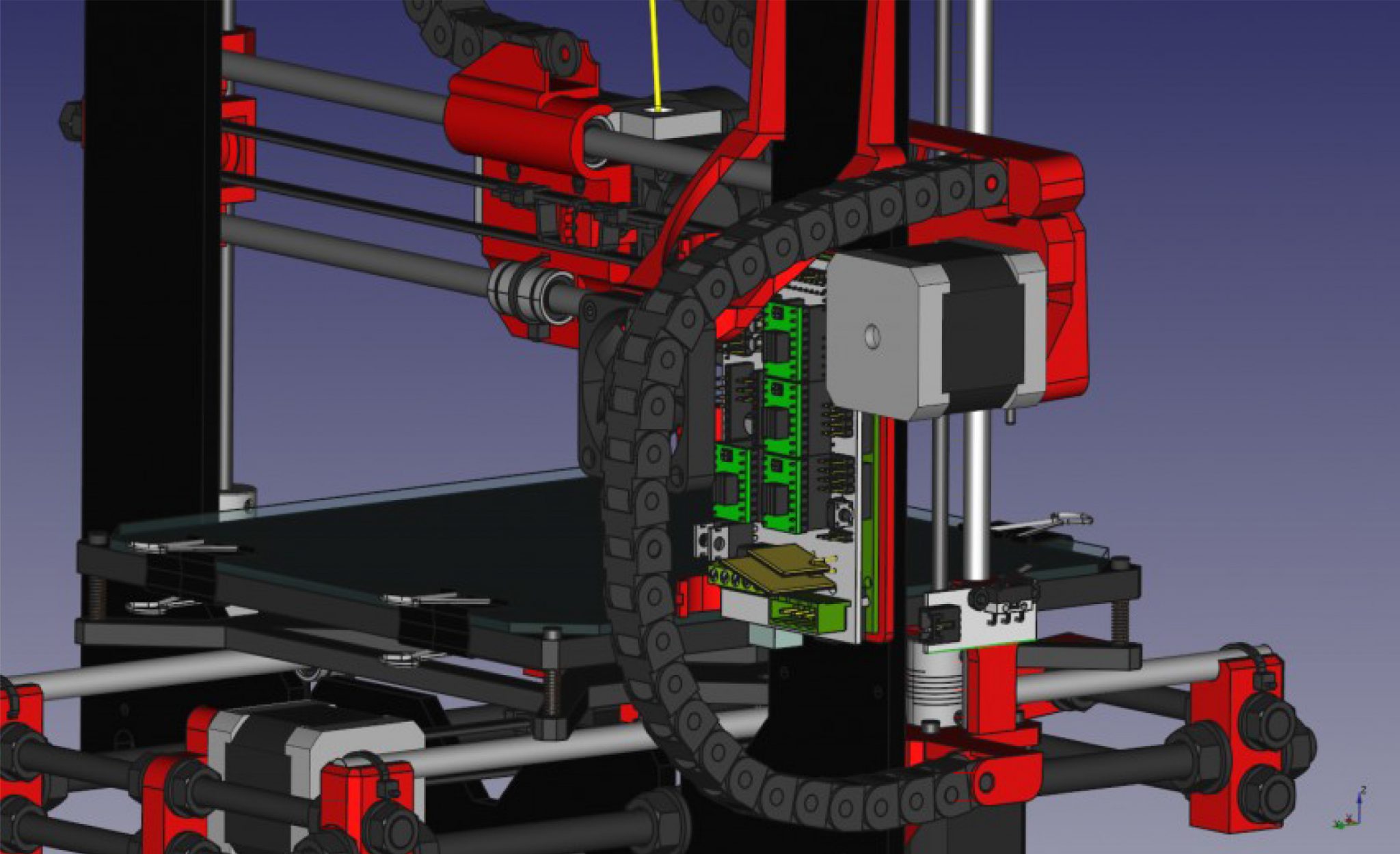

TECHMATIKS has proven mechanical system design team to make full mechatronic system under one roof from concept to equipment erection and post support for the custom equipment.

AESTHETIC DESIGN

It is extremely important for any manufacturer to have enclosure with elegant and professional look for better marketability. TECHMATIKS specializes in elegant looking enclosures and apt label design for both electronic enclosures and mechatronic systems. We design graphic overlay to suit the enclosures. In overall sense, aesthetic design contributes the product to become more robust. TECHMATIKS takes care of aesthetic design of produce right from preliminary stage of the design.

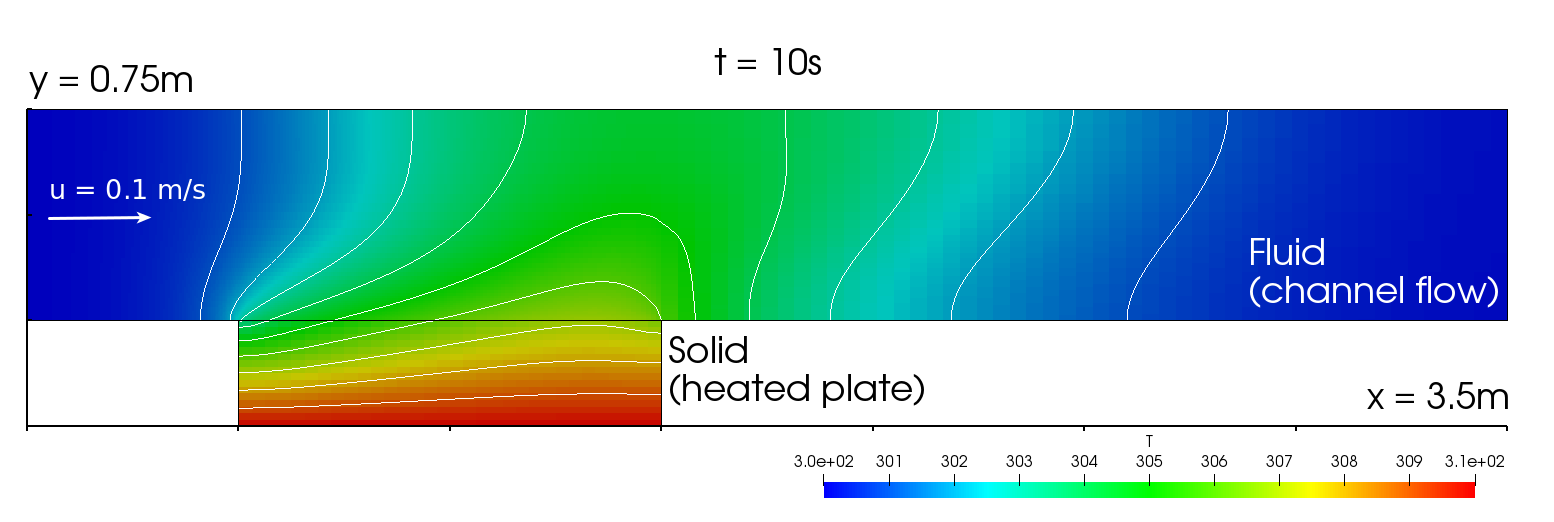

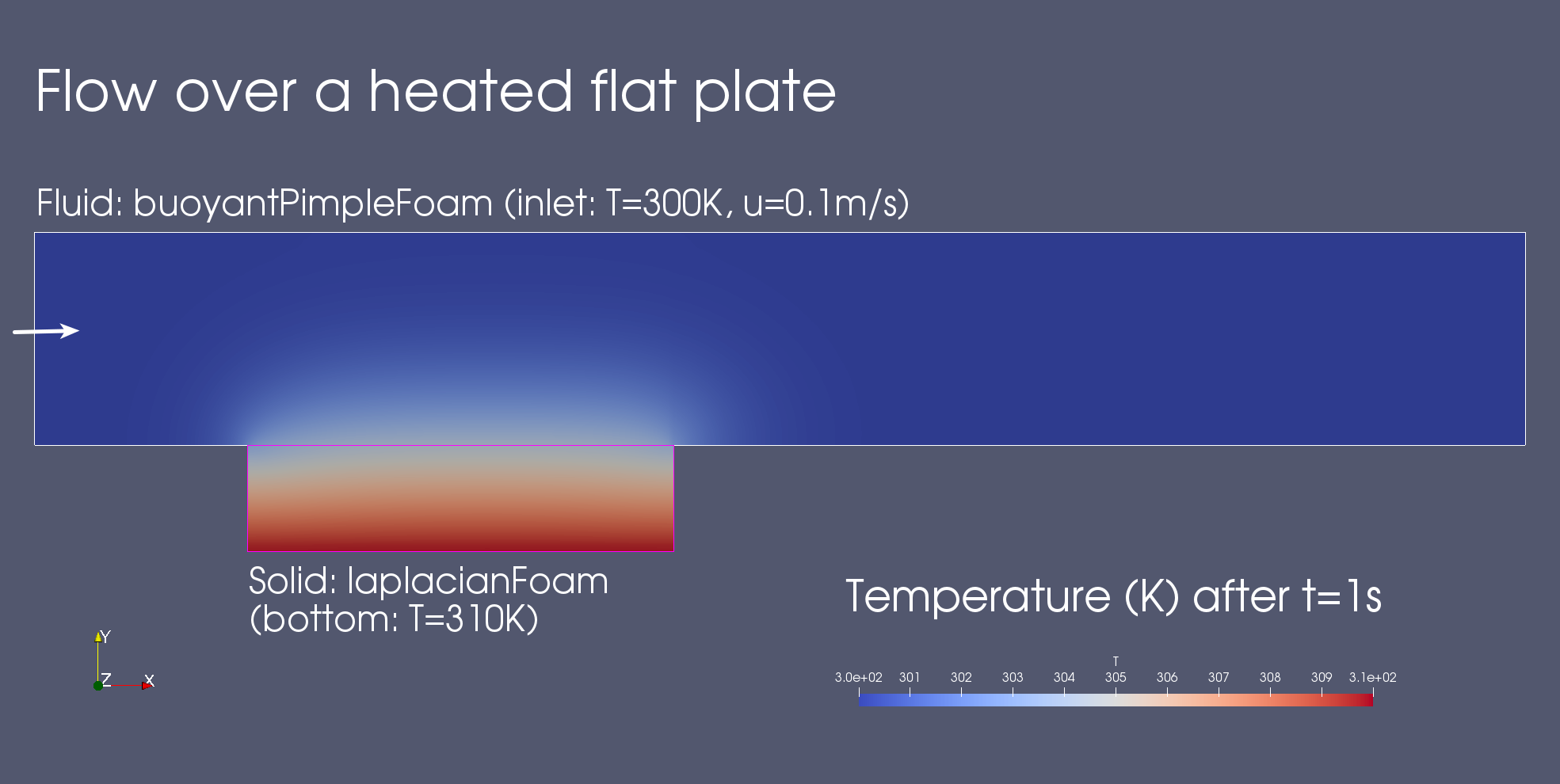

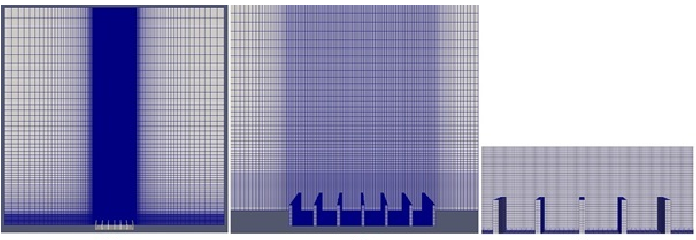

THERMAL DESIGN

Thermal management has become a critical element in today’s electronic design, as more compact designs have led to greater difficulty in removing heat from the system. In order to keep the components within their safe operating region, the operating temperature of the components must not exceed the manufacturer specified maximum temperature. A reduction in operating temperature increases the component life expectancy and therefore increases the reliability of the system. We at TECHMATIKS can handle thermal problems smartly. We use opensource based solutions viz. OpenFOAM, Code_ASTER etc. extensively. OpenFOAM is based on cutting- edge open source solver technology currently being used by leading companies and in a large number of industries with different requirements, such as automotive, aerospace, process technology, and power generation. We can rapidly implement new technology and ensure the greatest compatibility between our Custom tools and third-party software tools, with a high level of accuracy.

OPENFOAM®

OPENFOAM® is a toolbox for solving complex Computational Fluid Dynamics problems. It contains a wide range of physical models (including turbulence, wall treatment, thermodynamics, and mass transport), numerical methods and tools for pre and post-processing.

Developed at the Imperial College in London, OPENFOAM® offers impressive accuracy and is extensively validated in academic and industrial environments. It is continuously being developed and expanded by a large community of scientists, experts, and industrial customers, ensuring rapid implementation of new technologies. As a result, OPENFOAM® has recently replaced several commercial codes. OPENFOAM® is used for various applications by many industry leaders

Code_Aster is an open source software package for simulation in structural mechanics, including fatigue, damage, fracture, contact, geomaterials, porous media and multi-physics coupling. It was originally developed by EDF as an in-house application for safety-related simulations in nuclear energy environment. The software has been evaluated through independent comparisons in regards to analytical and experimental results and was bench marked against commercial codes. Code_Aster is used for various applications by industry-leading companies. Successful thermal management concepts can be applied in a variety of ways.

Employing heat shink, heat pipes, peltier cooling, phase change materials etc are common methods employed in thermal management systems in Electronic systems. In particular, they can be found in applications for industrial electronics, the automotive industry and aviation. Examples of this are: LED lighting systems, engine and transmission control systems, inverters, switches and DC power supplies. We at TECHMATIKS can do numerical modelling and simulation of practical thermal management systems and help to arrive at optimum and thermally efficient surfaces. Heat pipes are used where high heat need to be transferred. Standard heat pipes act as thermal superconductors, transmitting heat with minimal temperature drop in both directions.