ENGINEERING TEST SOLUTIONS

Advanced engineered system like engines, vehicles, motors, pumps, heavy processing machines, agricultural equipment, consumer appliances etc which are to be designed for higher performances and energy efficiency to remain competitive in market. We aid in developing such system by developing apt, innovative and accurate test establishment.

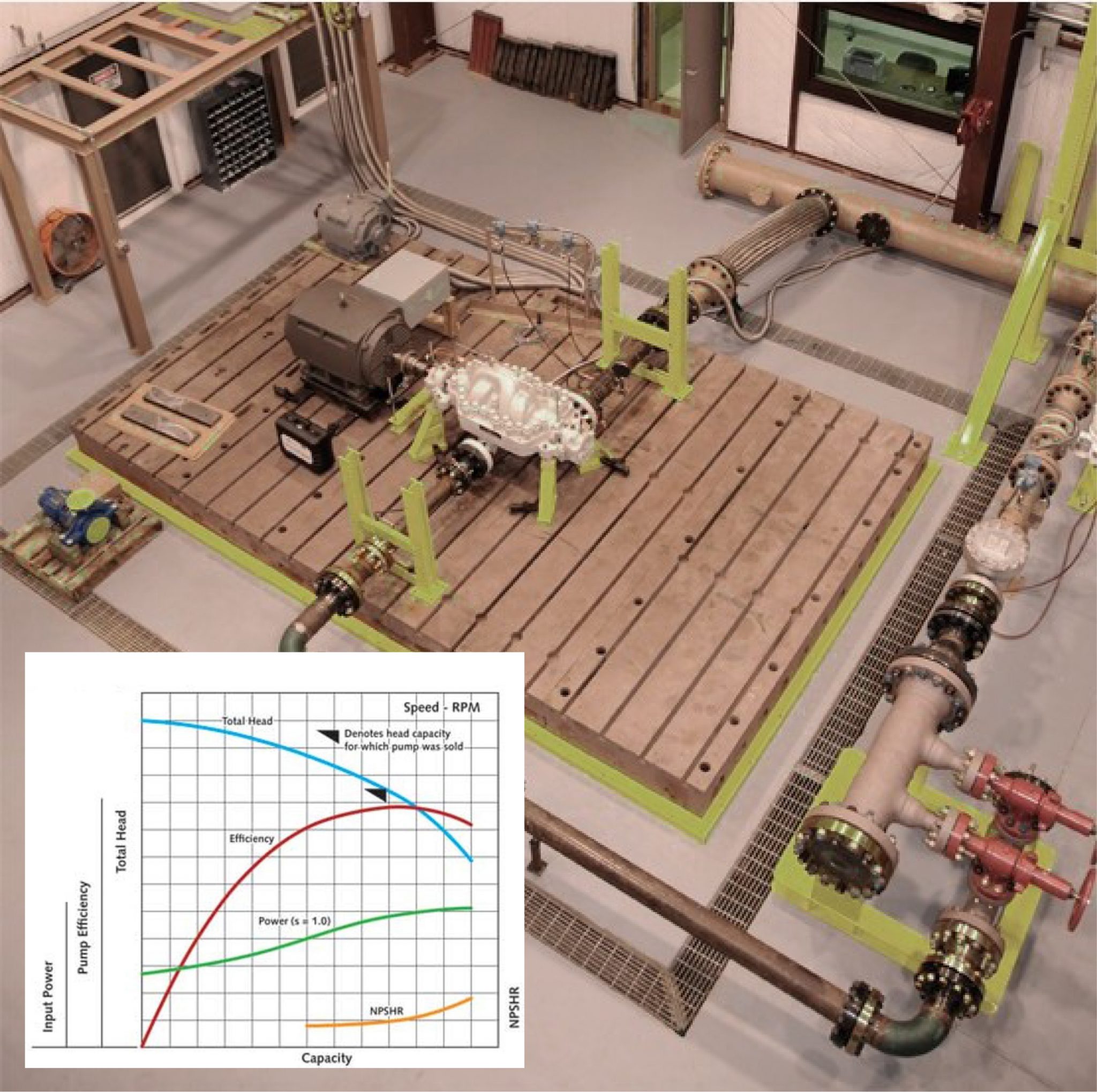

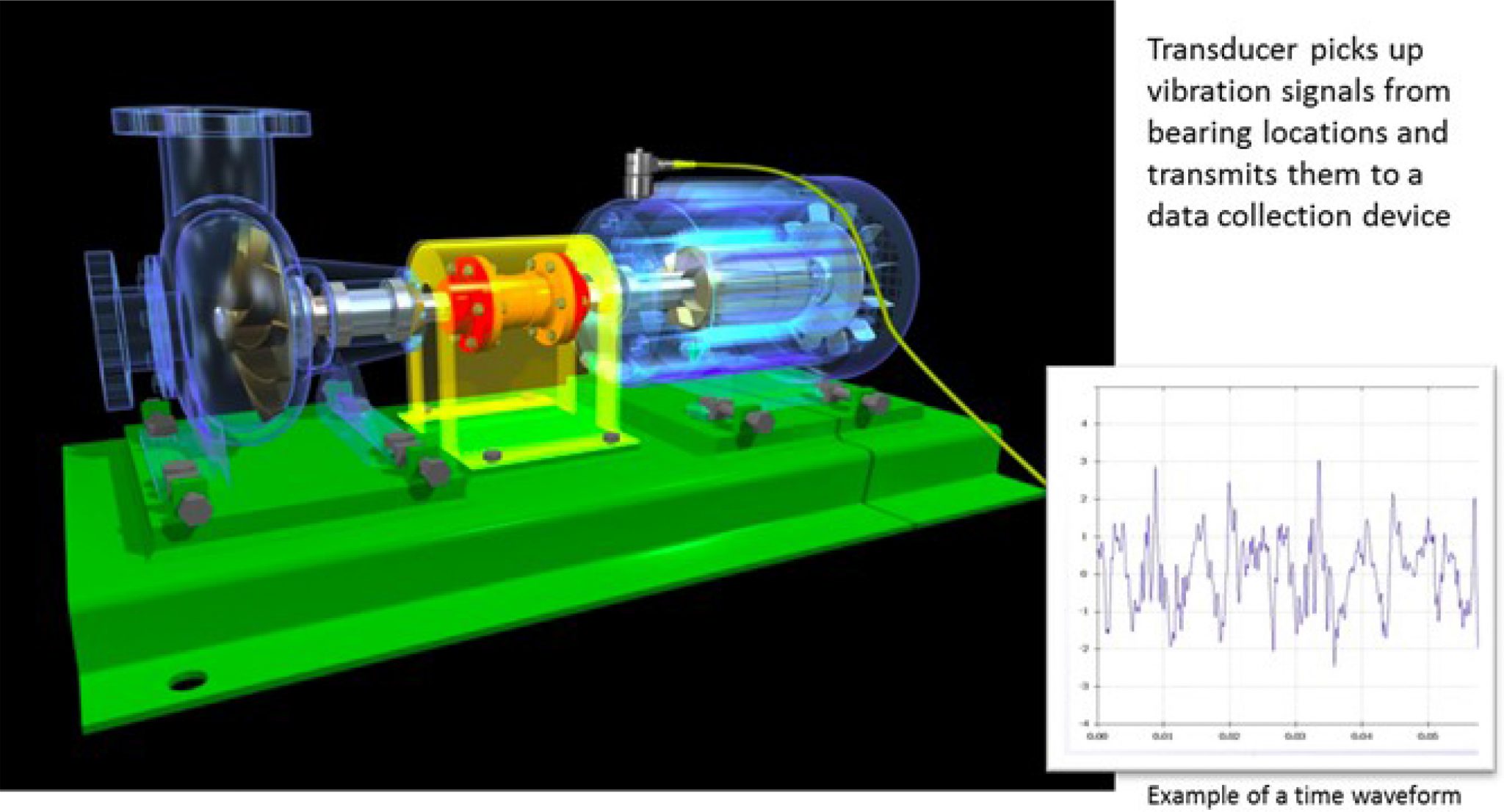

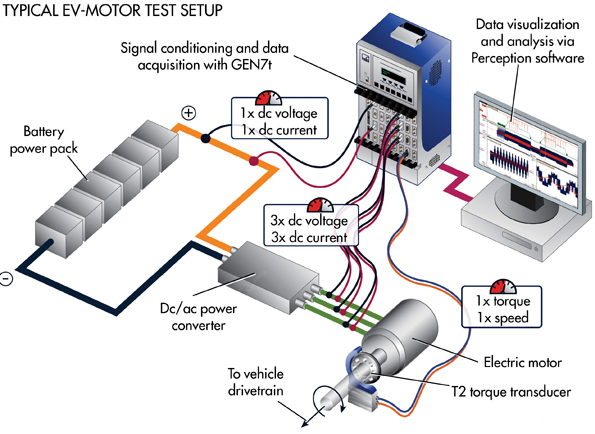

We at TECHMATIKS are expert in control system design and implementation. Specifically we can do control system for torque test systems like engine test beds where contol law is required for torque and speed control of eddy current & AC dynos, pump system to test impeller performance, vibration test and control system etc. We do control system design and implementation for any system. We start our process from preliminary to detailed modeling of system dynamics. We do simulation of system dynamics along with system identification of existing system/process. Evolve better control strategy and implement as code. We implement it on embedded processor or on a dedicated control computer depending on complexity of control law. Final implementation will be on the existing plant with industry standard signal processing modules.

Mostly we do with robust open source platform to cut down the cost. In short, we can implement any advanced control and test system to existing plant/process which bulls future modern research, design and test centers. We also do intermediate services for industry by identifying correct signal processing & acquition modules, purchase and install it in existing systems. Final goal of any test stand is data collection of various parameters like pressure, temperature, emission, torque, force, rotational speed, position, strain, vibration level etc. We do provide data acquisition, analysis and real time display solutions.

WE ARE OPEN TO CHALLENGES

There may be requirement from the mix of different measurements including pressure, temperature, current, shaft speed and what not. Our loggers makes it easier to troubleshoot and verify whether the raw data from different sensors are correct before you start your test. This helps to shorten test system development by saving time typically wasted on redoing configurations.

For example, heavy equipment manufacturers produce variations of powertrain systems for different vehicles like agricultural machines, construction equipment, automotives, and consumer appliances. Each system has unique specifications for functionality and performance, which means, every test has different requirements to integrate new sensors and industrial protocols. We are master in that.

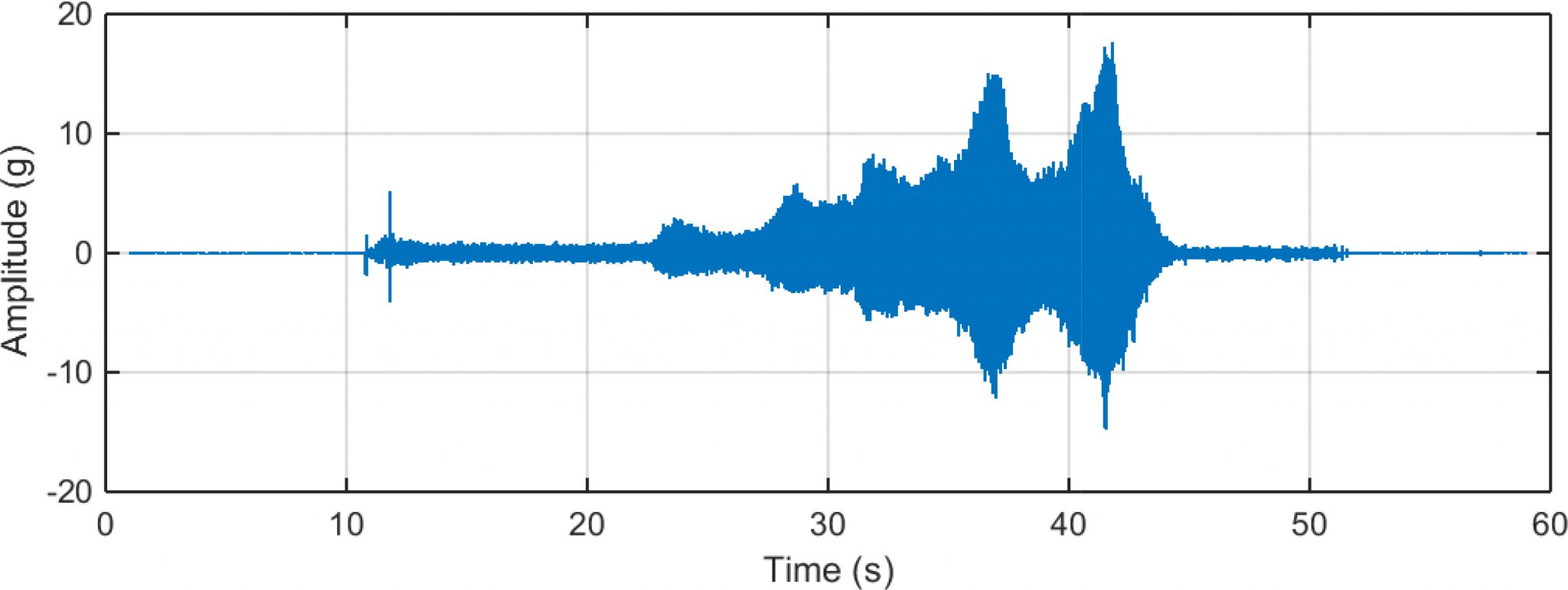

STRUCTURAL VIBRATION – TEST AND ANALYSIS SOLUTION(CASE STUDY)

VIBRATION OF CAR ENGINE

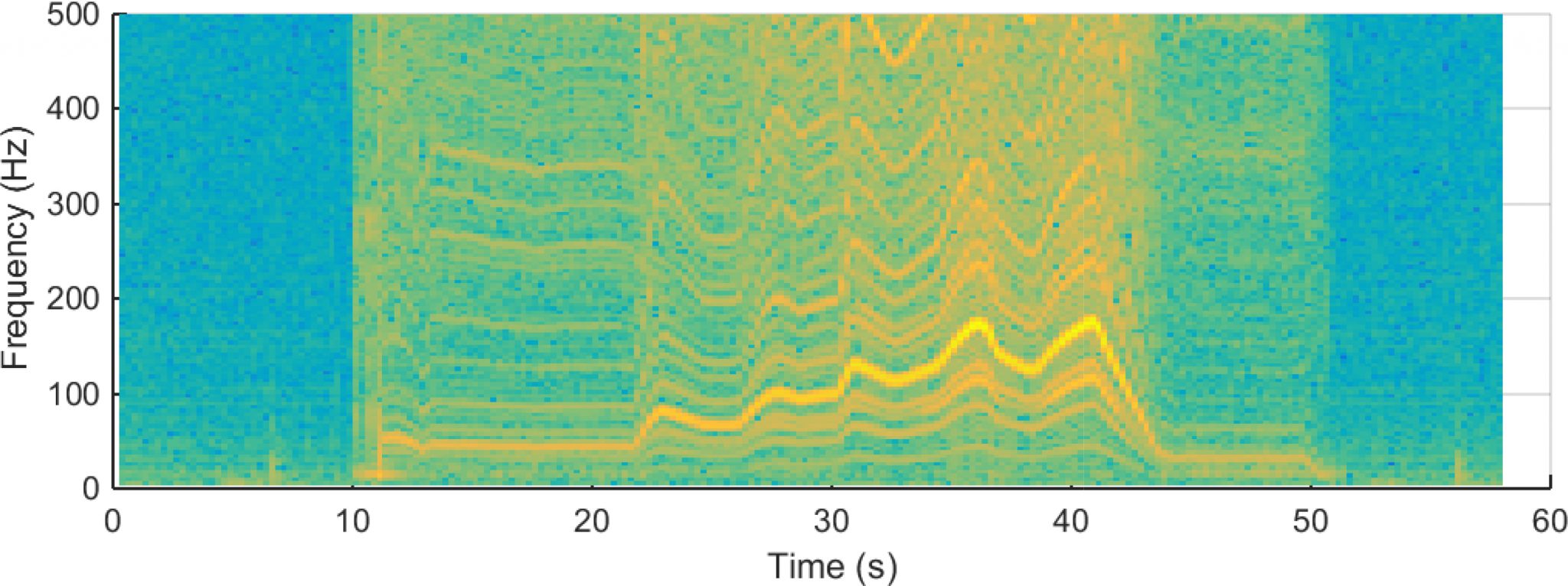

SPECTROGRAM OF CAR ENGINE

Vibration can result from a number of conditions, acting alone or in combination; and may be caused by auxiliary equipment, not just the primary equipment.Vibration can be both a sign and a source of trouble. Unchecked vibration can have potentially severe effects on machinery life, power consumption, and safety. Other times, vibration is just a normal part of machine operation, and should not cause undue concern. The difficulty is that most facilities personnel don’t possess the capabilities to discern the difference between acceptable, normal vibration and the kind that requires immediate attention to service or replace troubled equipment. This is where TECHMATIKS comes into picture.